Foreword

In today’s dynamic business climate, companies are looking for simple ways to reduce waste and improve profitability. Going through many business cycles or phases faster than ever, new technology initiatives must be affordable, easy to implement, and have a high, measurable rate of return.

In today’s dynamic business climate, companies are looking for simple ways to reduce waste and improve profitability. Going through many business cycles or phases faster than ever, new technology initiatives must be affordable, easy to implement, and have a high, measurable rate of return.

Companies approach their inventory planning in many different ways - from seat of the pants guessing, to team collaboration, to spreadsheets that may invoke more team collaboration and manual changes, to forecasting software and some to advanced planning solutions.

Business software solutions like accounting packages or ERP systems come with some level of inventory management or inventory control functionality but rarely do they include forecasting or demand planning. They rely on the user manually setting min and max levels and safety stock to control the inventory. There are stand-alone forecasting packages that offer dozens of statistical models that allow the user to select the one or ones they want to use, and some even provide automated forecasting in which the solution uses a best-fit approach.

The Business Problem

However, the question becomes a matter of how to use or interpret the results of forecasting to establish inventory stocking levels and plan effectively. Lacking anything else, what generally happens is that forecasts are used to set inventory levels and requirements. The user then manually sets min and max levels and ultimately purchasing and production quantities. This approach can be acceptable if only a few items are involved, but it can be a monumental task for hundreds or thousands of items. Relying on forecasting systems with a 40 to 60% accuracy attainment at the Item or SKU/ location level usually results in stock-outs for many items and excess inventory for others. Both results are very costly to the company.

Interpreting Forecasting Results

When you have a product with consistent demand and several years of history, forecasting tends to be relatively straightforward. However, what about products with extremely random or slow demand, or new products with no history? How do you forecast for these differing situations? This problem is particularly pronounced with high tech products that may have a sales life as short as a few months and a service life of several years.

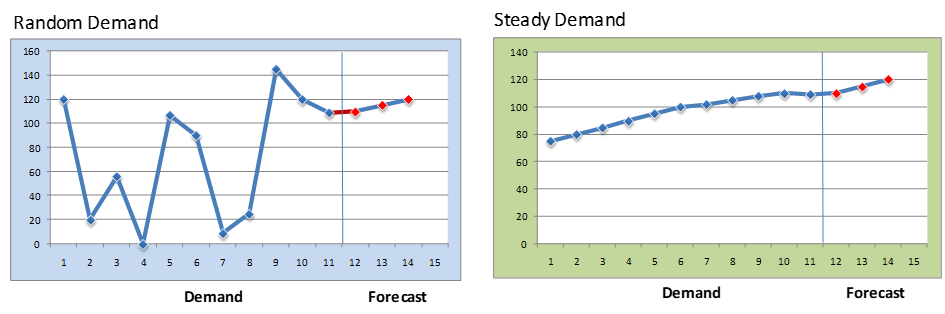

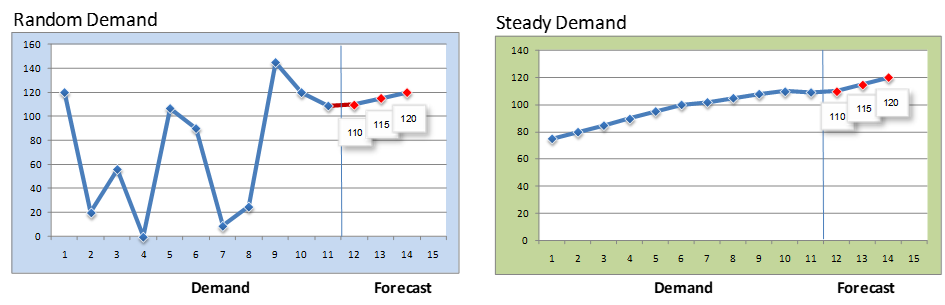

Below are two typical graphs of demand history. The one on the left has a random demand pattern and the one on the right shows a relatively constant demand stream.

In both cases, the forecast trend line may suggest the forecast ramping up slightly at around 110 in the first forecast month, 115 in the second and 120 in the third. Depending on the forecast model chosen, a random demand pattern may cause you to carry more inventory when you don’t need it and not enough on hand at times to meet a spike in demand.

In addition to a forecast, there are other factors to be considered when deciding how much inventory to stock. One factor is Service Level. This can dramatically affect your investment depending on the service levels you want to provide as illustrated in the graphs above.

Other factors include budget, carrying costs, planning horizon, lead times, and many more, such as:

-

When planning ocean shipments, a large number of possible replenishment options should be examined to figure out how to optimally load full containers, while meeting demand.

-

Which supplier should be used when one has higher costs and shorter lead times than another.

-

Suppliers may offer quantity discounts, so an important decision is “How much extra should I buy now, at a lower price, beyond what I need for the near future to be most cost effective?”

-

Positioning inventory properly across the supply chain and across items may be a major consideration. Centralizing inventory allows “pooling” of demand and a smaller total inventory quantity. However, sending inventory out to regional and field sites or retail locations could improve responsiveness to customer demands.

-

Your customers supply you with their forecast using you as a ready source of supply. How did they arrive at their numbers? Do you use their numbers entirely or do you adjust them? Should you be planning and forecasting for them instead?

Getting Value from Forecasting

You should understand that forecasting is an important first step, but not the only step in good inventory planning. The entire inventory planning process must work smoothly and be in-sync from forecasting to setting stocking levels, to calculating replenishment levels, to purchasing and production. Inventory optimization and rationalization completes the process to provide outstanding value.