Your company’s mission is to be the best supplier of your products on the market today. Most companies define what that means in terms of serving the customer. Ecommerce has dramatically changed the way companies must serve their customer. For example, your customers can send you an order over the Internet or by calling and they will get a return confirmation promptly. You will ship all orders within 24 hours. You will offer a variety of products that is both broad and deep.

Read MoreInventory Planning Blog

Tags: Inventory Planning, SAP, NetSuite, Demand Planning, Spreadsheets, inventory management, Inventory Planning Solutions

The Financial Metrics in Measuring a Well-Balanced Inventory – Part 2

Posted on Thu, Jun 01,2023@11:00 AM

This blog continues with the various financial/accounting measurements you can use. As stated previously, most small businesses use an ERP system from companies like SAP, NetSuite and Microsoft. But they fall short of providing inventory optimization and rationalization. Understanding and using some basic financial and accounting methods with an advanced inventory optimization solution will help get you there. It will also help keep you there.

Read MoreTags: Inventory Planning, SAP, NetSuite, Demand Planning, NetSuite Demand Planning

The Financial Metrics in Measuring a Well-Balanced Inventory – Part 1

Posted on Mon, May 01,2023@11:00 AM

Most small businesses use an ERP system from companies like SAP, NetSuite and Microsoft. But they fall short of providing inventory optimization and rationalization. Achieving a well-balanced, efficient inventory is no small task as supply chain complexity is ever increasing. How do you get there? How do you know when you have arrived? Understanding and using some basic financial and accounting methods with an advanced inventory optimization solution will help get you there. It will also help keep you there.

Inventory planning uses a wide range of variables and metrics, which generally include:

Read MoreTags: Inventory Planning, SAP, NetSuite, Demand Planning, Supply Chain, Inventory Planning Solutions, NetSuite Demand Planning

Valogix Advanced Inventory Planning and Optimization for NetSuite

Posted on Wed, Feb 01,2023@10:07 AM

As your business grows and gains in complexity, you may need to explore how advanced inventory planning and optimization capabilities can take your business to the next level. Valogix, a global award-winning partner of NetSuite. We offer a specialized multi-stage planning engine that more effectively plans inventories and compliments NetSuite.

Read MoreTags: Inventory Planning, NetSuite, Demand Planning, Valogix, Inventory Planning Solutions, NetSuite Demand Planning

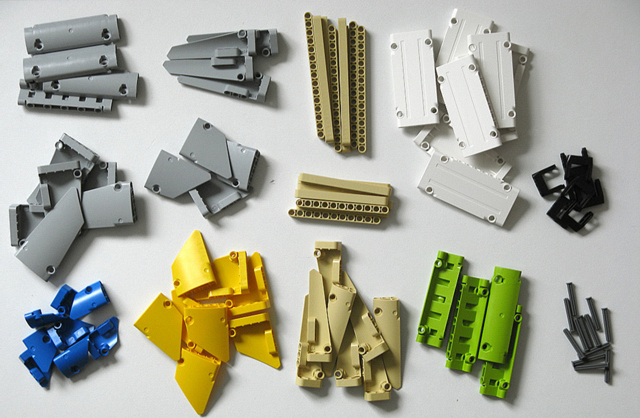

Spare parts inventory management is a prime candidate for advanced inventory planning and optimization solutions. With many diverse parts to manage and a lack of power tools, most companies with parts inventories have too many of the wrong parts. The result is unnecessary inventory expense, while still suffering service-limiting stock-outs.

Read MoreTags: Inventory Planning, Demand Planning, Inventory Planning Solutions

Forecasting customer demand is an important and necessary part of the chain of calculations needed to optimize inventory stocking levels. There are a wide variety of techniques that can be used, making forecasting a confusing and sometimes difficult process. If your goal is to not only forecast demand but also stock inventory at optimal levels, then forecasting must be combined with inventory planning and replenishment optimization algorithms to reach the goals of higher service levels with less inventory.

Forecasting customer demand is an important and necessary part of the chain of calculations needed to optimize inventory stocking levels. There are a wide variety of techniques that can be used, making forecasting a confusing and sometimes difficult process. If your goal is to not only forecast demand but also stock inventory at optimal levels, then forecasting must be combined with inventory planning and replenishment optimization algorithms to reach the goals of higher service levels with less inventory.

Tags: advanced inventory planning solutions, Demand Planning, forecasting software,, optimized inventory planning

There are some distinctions of business purchases, strategic and non-strategic. Strategic purchases are those that have a direct effect on the business and the bottom line. Non-strategic are those for everyday items like office supplies, travel, commodity items, etc. In the case of manufacturing companies, strategic purchases can be raw materials, production equipment, energy, skilled labor, computers, and business operating software.

Read MoreTags: advanced inventory planning solutions, cloud computing, Demand Planning, forecasting, optimized inventory planning